电话:13815578682

Details

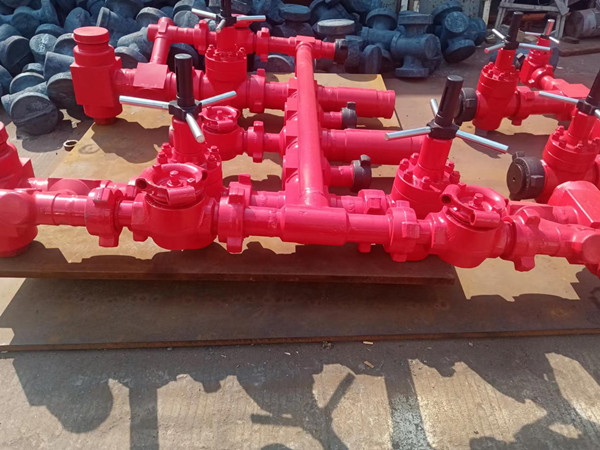

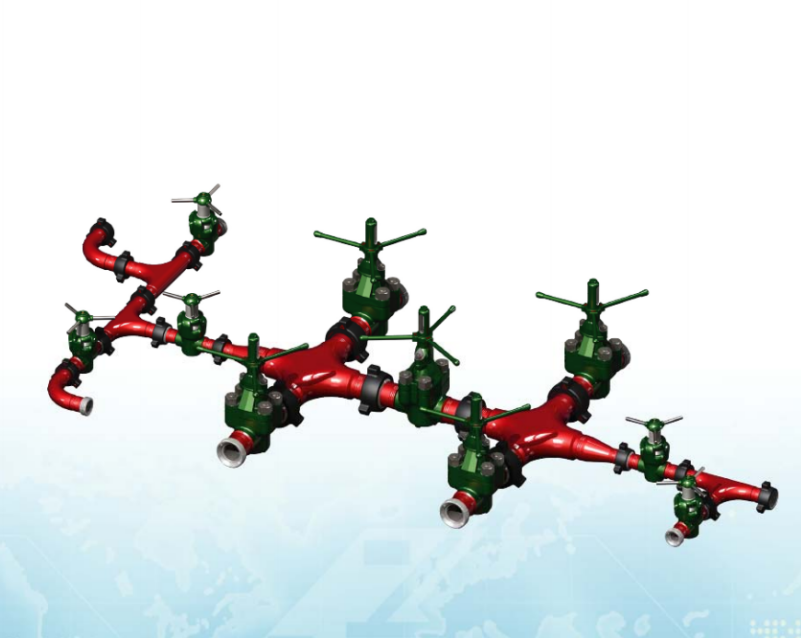

High Pressure Standpipe Manifold

High Pressure Standpipe Manifold consists of Z23Y100-5000psi & Z23Y50-5000psi mud valve, high pressure spherical union, high pressure core union, tee, high pressure hose, elbow, pressure gauge, spool etc.

Ground valve group adopts goose type tee with com pact structure, little fluid resistance and large power effectuality.

Adaptor spool adopted on rigid valve group can be directly used as single pipe on site.

High pressure union made of high strength alloy steel and heat treatment can create quick strip. As for being manufactured with special machining tool, it can cerate seal under fine sphere and core matched with sealing ring.

The gate and valve seat of Z23Y-5000psi mud valve are welded with carbide against erosion and corrosion, so that it can enlarge the working life, little operating torque.

Elbow, adaptor, tee and cross are made of high strength alloy steel, with suited wall thickness and fine heat treatment, so it can meet the requirement on strength and corrosion.

The part required at high precision, should be machined with special technique to ensure the manu facture quality, and the pressure part should be hydro static tested on strength and sealing property to ensure the quality.

Installation

First to clean up each sealing face and sealing groove of union and coat it with grease and get rid of dirt from the pipeline.

Check whether each joint is fastened or not.

As for shipping, to disassemble into parts, clean up pipes, coat the connections with grease and then, to be wrapped well up to avoid foreigner entrance and sealing surface damage.

Operation note and maintenance

Regularly inject mud gate valve with

grease to maintain the gate valve;

Regularly check whether al connect

ing position and fixing bolts are loose;

If leak around sealing position, the seal should be replaced immedi ately;

Keep the outer surface of the mani

fold clean and paint it against rust regularly.

- Prev:First

- Next:Kill Manifold